Drivetrain is the unsung hero beneath every vehicle’s performance, quietly orchestrating how power moves from the engine—or electric motor—to the wheels. While engines and motors often steal the spotlight, it’s the drivetrain that determines how effectively that power is put to use, shaping everything from acceleration and handling to fuel efficiency and traction.

For decades, drivetrain layouts like Front-Wheel Drive (FWD), Rear-Wheel Drive (RWD), and Four-Wheel Drive (4WD) have defined how vehicles behave on the road. But as Electric Vehicles (EVs) gain momentum, the traditional idea of drivetrain architecture is rapidly shifting. Dual motor setups, torque vectoring, and in-wheel motors are redefining how power is distributed, offering drivers more control and precision than ever before.

Understanding how drivetrains function—and how they differ across Vehicle Types—is essential not just for gearheads, but for anyone curious about how cars truly move. Whether you’re navigating icy roads, climbing off-road terrain, or optimizing efficiency in an EV, the drivetrain plays a central role in that experience. This article explores what a drivetrain is, the various types available, and how each one shapes the driving dynamics of modern vehicles.

What Is a Drivetrain?

A drivetrain is the system in a vehicle that transmits power from the engine or electric motor to the wheels, making movement possible. It acts as the crucial bridge between power generation and road performance. Without this technology, a vehicle—regardless of how powerful its engine or motor is—would remain motionless.

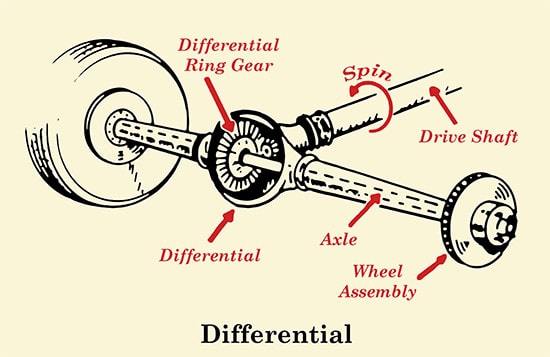

In technical terms, the drivetrain includes all the components responsible for delivering torque to the wheels. This typically involves the transmission, driveshaft, differential, and axle shafts. These parts work together to regulate how power is distributed, ensuring the vehicle moves efficiently, responds to acceleration, and adapts to terrain or traction conditions.

It’s important to understand that the drivetrain does not include the engine or motor—that’s part of the powertrain. While the powertrain encompasses everything from power generation to power delivery, the drivetrain strictly focuses on the delivery mechanism. In electric vehicles (EVs), the drivetrain may look different due to the absence of complex transmissions or gearboxes, but its core function remains the same: getting power to the ground.

Whether in a gas-powered car or a fully electric SUV, the drivetrain plays a pivotal role in defining how a vehicle handles, how much energy it consumes, and how well it performs under different driving scenarios.

How a Drivetrain Works

At a glance, driving may seem simple: you press the accelerator, and the vehicle moves forward. But behind that smooth motion lies a sophisticated mechanical chain—the technology—responsible for transmitting power efficiently from the engine or electric motor to the wheels.

In conventional internal combustion engine (ICE) vehicles, the process begins when the engine generates rotational force (torque). This torque is passed through the transmission, which adjusts gear ratios to optimize power for speed or force. From there, it moves through the driveshaft (if rear or all-wheel drive), then enters the differential, which divides power between the wheels—especially important when turning. Finally, the power reaches the axles, rotating the wheels and propelling the vehicle.

In electric vehicles (EVs), the drivetrain functions on similar principles but with fewer moving parts. Instead of a complex multi-gear transmission, many EVs use a single-speed reduction gear. The electric motor directly generates torque and sends it through this gear system, then to the differential and axles, much like in ICE drivetrains. Dual-motor EVs (such as AWD Teslas or Rivians) add another layer of control, using software to distribute torque between the front and rear axles independently for improved traction and performance.

A key part of drivetrain functionality is traction management—especially in slippery or uneven conditions. Modern drivetrains use sensors and electronic systems (like traction control and torque vectoring) to adjust how much power goes to each wheel. This allows the vehicle to maintain grip, improve stability, and optimize energy efficiency on the fly.

Whether simple or advanced, the drivetrain’s job remains consistent: convert power into motion, safely and efficiently.

Drivetrain vs Powertrain: What’s the Difference?

Although often used interchangeably, Drivetrain and Powertrain are not the same thing. The distinction is subtle but important—especially when comparing vehicle systems across internal combustion engines (ICE) and electric vehicles (EVs).

The powertrain refers to the entire system responsible for generating and delivering power to the wheels. This includes the engine or electric motor, the drivetrain itself, and any supporting components like the transmission, battery (in EVs), and inverter. In other words, the powertrain covers the full journey of energy—from production to propulsion.

The drivetrain, on the other hand, is a subset of the powertrain. It only includes the components involved in transmitting power from the transmission to the wheels—excluding the energy source itself. This means no engine, no battery, no motor; just the transmission, driveshaft, axles, and differential. Its focus is solely on delivering power, not generating it.

Let’s break it down further in a comparison table:

| Component | Powertrain | Drivetrain |

|---|---|---|

| Engine / Electric Motor | Included | Not included |

| Transmission | Included | Included |

| Driveshaft | Included | Included |

| Axles | Included | Included |

| Differential | Included | Included |

| Battery (in EVs) | Included | Not included |

| Inverter (in EVs) | Included | Not included |

This distinction becomes especially clear in electric vehicles. An EV drivetrain may consist of just a reduction gear, axle, and differential, while the powertrain includes the electric motor, inverter, and battery pack—essential to generating and controlling electric power.

So why does the distinction matter? Understanding what each system includes can help drivers better comprehend maintenance requirements, efficiency, and performance characteristics. For example, drivetrain repairs typically focus on gears, axles, or differentials—while powertrain issues may involve the motor or battery system.

In summary, the drivetrain delivers power, while the powertrain produces and delivers it. Knowing the difference can give you deeper insight into how your vehicle operates—especially as the automotive world shifts from mechanical to electrified systems.

Main Types of Drivetrain Systems

Modern vehicles rely on several distinct drivetrain configurations, each tailored to a specific blend of performance, efficiency, cost, and terrain handling. Understanding the differences between these systems—Front-Wheel Drive (FWD), Rear-Wheel Drive (RWD), All-Wheel Drive (AWD), and Four-Wheel Drive (4WD)—can help consumers make smarter decisions when choosing a vehicle, especially as these setups evolve in the context of electric mobility.

Front-Wheel Drive (FWD)

Front-Wheel Drive (FWD) is one of the most common drivetrain configurations, particularly in compact cars, sedans, and urban vehicles. In an FWD system, the engine or motor delivers power to the front wheels only, which are responsible for both driving and steering the vehicle.

This layout became especially popular in the late 20th century due to its cost-effectiveness, space efficiency, and fuel economy. By placing the drivetrain components—engine, transmission, differential—at the front of the car, automakers reduce complexity and free up space inside the cabin or trunk.

From a performance standpoint, FWD vehicles typically offer stable handling under normal driving conditions, especially on wet or snowy roads, since the weight of the engine sits above the drive wheels, increasing traction. However, FWD does have limitations. Because the front wheels must both steer and propel, there’s an inherent compromise in handling. Torque steer—where the steering wheel pulls during hard acceleration—is also a common issue in high-powered FWD cars.

FWD is ideal for commuting, city driving, and cost-conscious buyers, but may fall short in performance driving or off-road situations.

Advantages of FWD:

- Lower manufacturing cost

- Better fuel economy

- More interior space

- Improved traction in slippery conditions

Disadvantages:

- Less responsive handling under high load

- Torque steer under acceleration

- Not ideal for performance or rugged terrain

Rear-Wheel Drive (RWD)

Rear-Wheel Drive (RWD) transmits power to the rear wheels only, allowing the front wheels to focus solely on steering. This separation of functions provides better weight distribution, particularly in performance vehicles and trucks.

RWD is traditionally associated with sports cars, luxury sedans, and pickups, where handling, balance, and towing capacity are prioritized. Because the rear wheels handle propulsion, RWD vehicles often exhibit superior cornering dynamics and acceleration balance, especially in dry conditions. This makes them the preferred choice for driving enthusiasts and manufacturers of high-performance cars.

However, the Achilles’ heel of RWD is low traction in slippery or icy conditions. Since the rear wheels carry less of the vehicle’s weight (unlike FWD), they can lose grip more easily on wet or snowy roads. To combat this, modern RWD cars often include electronic stability control or traction management systems.

In EVs, RWD configurations are increasingly common, especially in entry-level variants (such as single-motor Tesla Model 3s), as electric motors can be mounted directly on the rear axle without needing a long driveshaft.

Advantages of RWD:

- Improved balance and handling

- Better acceleration and towing performance

- No torque steer

- Preferred for high-power applications

Disadvantages:

- Poor traction in snow or rain

- Heavier due to driveshaft and rear differential

- Reduced efficiency in stop-and-go traffic

All-Wheel Drive (AWD)

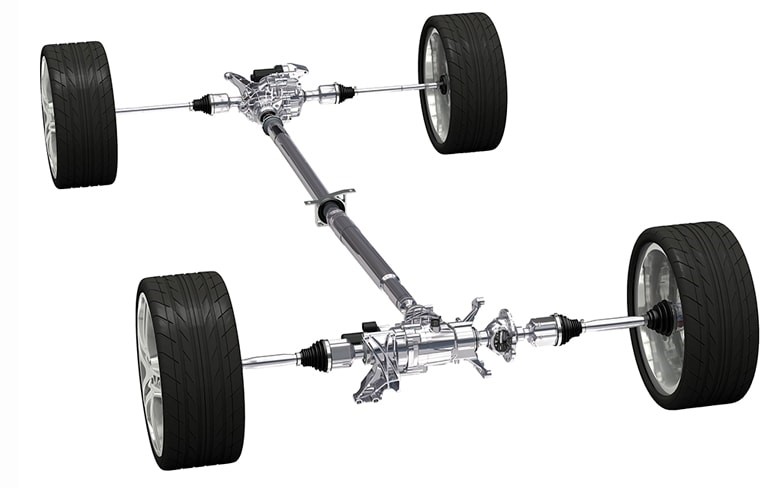

All-Wheel Drive (AWD) systems are designed to deliver power to all four wheels simultaneously—either full-time or on-demand—depending on traction conditions. Unlike traditional 4WD, AWD systems operate seamlessly in the background, with no need for driver intervention. They rely on complex electronic sensors, differentials, and clutches to determine how much power should be sent to each axle or wheel.

This setup is particularly common in crossovers, SUVs, and high-performance sedans, where a balance between daily usability and enhanced traction is desired. AWD shines in wet, snowy, or uneven road conditions, offering better grip and vehicle stability without sacrificing comfort or fuel efficiency.

In the context of electric vehicles, AWD systems often involve a dual-motor configuration—one motor on the front axle, another on the rear. This allows not only precise torque distribution but also improved acceleration, as the system can independently control each motor. Vehicles like the Tesla Model Y AWD, Hyundai Ioniq 5 AWD, and Rivian R1T use this configuration to deliver both efficiency and performance.

Types of AWD Systems:

- Full-time AWD: Constantly active and typically uses a center differential.

- Part-time/Automatic AWD: Operates mainly in 2WD and activates AWD only when needed.

Advantages of AWD:

- Superior traction and grip on varying surfaces

- Enhanced safety in poor weather conditions

- Smooth, automatic torque management

- Widely available in EVs with dual-motor setups

Disadvantages:

- Higher cost and mechanical complexity

- Increased weight and reduced fuel economy

- Not ideal for extreme off-roading (compared to 4WD)

Four-Wheel Drive (4WD)

Four-Wheel Drive (4WD) is the drivetrain configuration engineered for off-road dominance and rugged conditions. Unlike AWD, 4WD systems are typically driver-activated via a lever, button, or rotary switch, allowing the driver to engage or disengage power to all four wheels manually.

Traditional 4WD uses a transfer case, which splits power evenly between the front and rear axles. Many systems also include low-range gearing, which provides the torque needed for crawling over rocks, sand, or steep inclines. This makes 4WD a staple in trucks, SUVs, and utility vehicles designed for heavy-duty tasks or terrain.

Although 4WD systems can be found in some off-road-capable EVs (like the GMC Hummer EV or Rivian R1T), their structure is quite different from mechanical 4WD in ICE vehicles. In EVs, software manages torque vectoring across independent motors, mimicking traditional 4WD behavior without the need for transfer cases or driveshafts.

Advantages of 4WD:

- Maximum traction in off-road or extreme conditions

- Torque delivery through low-range gearing

- Tough, durable design for rugged environments

Disadvantages:

- Heavier and more mechanically complex

- Lower fuel economy (especially when engaged)

- Less suitable for everyday driving

FWD vs RWD vs AWD vs 4WD: Comparison Table

| Feature / System | FWD | RWD | AWD | 4WD |

|---|---|---|---|---|

| Driven Wheels | Front | Rear | All (auto or full-time) | All (manual activation) |

| Typical Use | Economy cars, city driving | Sports cars, trucks | Crossovers, EVs, premium sedans | Off-road SUVs, trucks |

| Traction in Snow | Moderate | Poor | Excellent | Excellent |

| Handling | Understeer-prone | Balanced / Oversteer-prone | Neutral (dynamic distribution) | Rough, sometimes harsh |

| Fuel Efficiency | High | Moderate | Lower (than FWD/RWD) | Lowest |

| Cost & Complexity | Lowest | Moderate | High (due to sensors/software) | Highest |

| EV Compatibility | Less common | Common (single-motor EVs) | Very common (dual-motor EVs) | Available in advanced off-road EVs |

Drivetrain in Electric Vehicles

Electric vehicles (EVs) have not only revolutionized how cars are powered but also redefined how power is delivered to the wheels. The traditional drivetrain layouts found in internal combustion engine (ICE) vehicles—such as front-wheel drive (FWD), rear-wheel drive (RWD), and all-wheel drive (AWD)—still exist in EVs, but the way they’re implemented is fundamentally different due to the unique nature of electric propulsion.

Simplified Mechanical Structure

Unlike ICE vehicles that require complex transmissions, clutches, driveshafts, and gearboxes, many EVs use a single-speed transmission. This is possible because electric motors can deliver instant torque across a wide RPM range, eliminating the need for multi-gear systems. As a result, the EV drivetrain is mechanically simpler, more compact, and less prone to maintenance issues.

For example, a rear-wheel-drive electric vehicle like the Tesla Model 3 RWD has a single electric motor mounted at the rear axle, directly driving the rear wheels. No need for a central driveshaft or multi-speed gearbox—just efficient torque delivery through a reduction gear.

Dual Motor and AWD Integration

One of the major advantages of EV drivetrains is the ease of implementing all-wheel drive. Instead of connecting front and rear axles via a transfer case or driveshaft, EVs can simply place a motor on each axle. This is known as a dual-motor AWD setup, and it allows real-time torque vectoring between the front and rear—controlled by software.

Vehicles like the Tesla Model Y AWD, Hyundai Ioniq 5 AWD, and Rivian R1T use this configuration to great effect. The benefits include:

- Improved traction in rain, snow, or off-road conditions

- Faster acceleration thanks to power from both axles

- Dynamic stability control through instant torque adjustments

This level of control was previously unthinkable in mechanical drivetrains and now represents a leap forward in drivetrain technology.

Advanced Features: Torque Vectoring & In-Wheel Motors

Some high-end EVs and performance-focused electric platforms also offer torque vectoring, where each wheel can receive a different amount of torque. This not only enhances handling in corners but also improves safety and responsiveness under variable traction conditions.

An emerging innovation is the in-wheel motor, where the motor is integrated directly into each wheel hub. This removes the need for axles and differentials entirely, enabling independent wheel control. Although still rare due to cost and engineering complexity, in-wheel motors promise a future of fully modular, software-defined drivetrains with unprecedented flexibility and precision.

Thermal Management and Regenerative Braking

Drivetrain efficiency in EVs also depends on how well the vehicle manages thermal loads during high-torque driving, and how effectively it uses regenerative braking to recover energy. The drivetrain must be optimized not just for power delivery but also for energy conservation, especially since EV range anxiety remains a concern for many buyers.

Modern EV drivetrains integrate:

- Cooling systems for the motor and power electronics

- Software for adjusting regen braking strength

- Battery-to-wheel efficiency optimization algorithms

Together, these technologies elevate the EV drivetrain from a mechanical system to an intelligent, self-regulating component of the vehicle’s digital architecture.

Factors That Affect Drivetrain Performance

The performance of a drivetrain—whether in a traditional gasoline vehicle or a cutting-edge electric model—depends on more than just the layout. A variety of mechanical, environmental, and design-related factors determine how effectively a drivetrain can deliver power, maintain traction, and influence overall driving dynamics.

Torque Delivery and Distribution

At the heart of any drivetrain is its ability to deliver torque. How quickly and evenly that torque is distributed to the wheels determines acceleration, responsiveness, and handling. In ICE vehicles, torque builds gradually as RPM increases, while in EVs, instant torque is available from a standstill.

In dual-motor AWD EVs, for example, the system can distribute torque dynamically between the front and rear axles, depending on road conditions. This kind of active torque vectoring ensures better grip and balance during high-speed cornering or slippery surfaces.

Weight Distribution

Drivetrain layout significantly affects vehicle balance and center of gravity. For instance:

- FWD systems concentrate most of the weight at the front, which can lead to understeer during aggressive cornering.

- RWD offers better front-rear weight balance, often improving stability and steering feel.

- AWD and 4WD vehicles tend to be heavier due to additional components, which can affect acceleration and fuel economy.

In EVs, where the battery pack sits low across the chassis, weight distribution tends to be more uniform, contributing to a lower center of gravity and improved drivetrain efficiency.

Tire Grip and Surface Conditions

Even the most advanced drivetrain cannot perform effectively without adequate traction. Road surface, tire type, and weather all influence how power is transferred to the ground. AWD and 4WD systems offer clear advantages in rain, snow, or loose gravel, where maintaining grip becomes challenging.

Vehicles equipped with traction control systems (TCS) and electronic stability control (ESC) use drivetrain sensors to monitor wheel slip and automatically adjust power delivery—enhancing safety and drivability in poor conditions.

Gear Ratios and Transmission Efficiency

The type and efficiency of a vehicle’s transmission directly affect how smoothly the drivetrain operates. A well-matched gear ratio ensures that the engine or motor remains in its optimal power band while minimizing energy losses.

- In ICE vehicles, gear selection is crucial for fuel economy and responsiveness.

- In EVs, single-speed transmissions reduce mechanical complexity and energy waste, but high-performance EVs may adopt multi-speed gearboxes for better efficiency at high speeds.

Vehicle Load and Towing Capacity

The weight a vehicle carries or tows plays a huge role in drivetrain stress. For trucks or utility vehicles, drivetrain components must handle high torque under load, especially in 4WD systems designed for towing or off-road use.

Manufacturers often upgrade the drivetrain (heavier axles, low-range gears, reinforced differentials) for vehicles meant for heavy-duty applications. In EVs, towing capacity depends not only on motor output but also on drivetrain cooling and software torque management.

Regenerative Braking (in EVs)

In electric drivetrains, regenerative braking is an essential performance factor. It allows the vehicle to convert kinetic energy back into stored electrical energy during deceleration. The drivetrain must be engineered to handle this bi-directional power flow smoothly, without compromising braking performance.

Many EVs allow drivers to adjust regen levels, offering a more customizable driving feel—from smooth coasting to one-pedal driving.

Software Control and Sensors

Modern drivetrains are heavily reliant on ECUs (Electronic Control Units) and sensor data to deliver optimal performance. Software can control:

- Torque split between wheels

- Drivetrain cooling

- Power limiter modes (eco/sport)

- Slip detection and correction

In EVs, these software layers become even more crucial, allowing manufacturers to push over-the-air (OTA) updates that enhance drivetrain behavior without mechanical changes.

Maintenance and Reliability of Drivetrain Systems

A well-functioning drivetrain is essential for a smooth, safe, and efficient driving experience. While modern drivetrains are built to last—especially in electric vehicles (EVs)—they still require routine care to prevent long-term damage and performance issues. Understanding the maintenance needs and reliability characteristics of various drivetrain types can help vehicle owners reduce repair costs and prolong vehicle life.

Common Drivetrain Components That Require Attention

Regardless of the drivetrain configuration (FWD, RWD, AWD, or 4WD), several key components must be monitored and maintained:

- Transmission fluid (in ICE vehicles): Essential for lubrication and cooling; neglecting it can lead to overheating or gear slippage.

- Differential fluid: Should be changed periodically to ensure smooth operation of gear teeth, especially in AWD/4WD setups.

- CV joints and axles: These parts endure constant stress and are vulnerable to wear, especially in FWD vehicles.

- Driveshaft and U-joints (in RWD/4WD): Regular inspections prevent vibration and drivetrain imbalance.

- Transfer case (4WD only): Requires fluid changes and checks to maintain proper gear engagement and torque split.

Regular maintenance of these parts not only prevents failure but also ensures fuel efficiency, ride quality, and acceleration performance.

EV Drivetrain Maintenance: Simpler, But Still Essential

One of the biggest advantages of electric vehicles is their simplified drivetrain design. With no internal combustion engine, clutch, or multi-speed transmission, many of the traditional failure points are eliminated.

That said, EV drivetrains still require care in several areas:

- Reduction gear lubrication: Though less complex, the single-speed gearbox still needs fluid.

- Cooling systems: Thermal management is critical for the longevity of electric motors and power electronics.

- Regenerative braking system: While it reduces brake pad wear, it introduces new electronic systems that must be periodically tested.

- Software and sensors: Periodic diagnostics ensure that the drivetrain control systems are functioning properly, especially in dual-motor AWD EVs where torque distribution is software-managed.

EVs generally have fewer moving parts, which translates into lower maintenance costs, but that doesn’t mean they’re maintenance-free.

Signs of Drivetrain Problems

Whether in a gas-powered vehicle or an EV, early detection of drivetrain issues is key to preventing expensive repairs. Common warning signs include:

- Vibrations or clunking sounds under acceleration or deceleration

- Grinding or whining noises from beneath the car

- Uneven power delivery or hesitation when accelerating

- Fluid leaks near the transmission or differential

- Dashboard warning lights, especially in modern vehicles with drivetrain sensors

Ignoring these symptoms can lead to major failures, such as a seized transmission, broken axle, or differential lock-up—all of which can disable the vehicle.

Reliability by Drivetrain Type

Each drivetrain layout comes with its own reliability profile:

- FWD: Generally reliable and cheap to maintain due to its compact design, but vulnerable to CV joint wear.

- RWD: Durable and mechanically straightforward, though susceptible to driveshaft and differential issues over time.

- AWD: More complex with more parts to maintain, such as electronic torque couplers and dual differentials.

- 4WD: Built for durability, but prone to higher wear in off-road use, and requires vigilant fluid maintenance.

Electric drivetrains, by contrast, are often praised for their high reliability, especially due to the absence of high-heat, high-friction components like clutches and torque converters.

Preventive Maintenance Tips

To keep any drivetrain system in top shape:

- Follow the manufacturer’s maintenance schedule for fluid changes

- Inspect undercarriage for leaks or rust on moving parts

- Rotate tires regularly to reduce strain on differential systems

- Keep software updated (for EVs with OTA or dealer-based updates)

- For AWD/4WD: engage and disengage the system occasionally to prevent sticking mechanisms

Taking these simple steps can help avoid costly breakdowns and ensure your drivetrain performs efficiently for years to come.

Drivetrains, though largely hidden beneath the vehicle, are one of the most critical systems in modern transportation. With the right care—whether you’re driving a city-friendly FWD compact or a dual-motor AWD EV—you can enjoy the full potential of your vehicle’s power and control.

The Future of Drivetrain Technology

As the automotive industry undergoes its most significant transformation in over a century, the future of drivetrain systems is being shaped by electrification, digitalization, and sustainability. While traditional mechanical systems dominated the 20th century, tomorrow’s drivetrains will be smarter, cleaner, and far more integrated with vehicle software ecosystems.

Shift from Mechanical to Software-Defined Drivetrains

In the era of internal combustion engines (ICE), drivetrain systems relied on mechanical linkages, gearboxes, and transfer cases to distribute power. But as electric motors replace engines, and software replaces levers and cables, we’re witnessing the rise of the software-defined drivetrain.

Modern EVs use:

- Dual or quad motor setups (e.g., one motor per axle or wheel)

- Smart torque vectoring algorithms

- Adaptive power delivery based on sensor input and driving conditions

The result is a drivetrain system that can predictively adjust power distribution, rather than reactively respond. Future systems may even integrate artificial intelligence (AI) to learn from a driver’s habits and optimize performance accordingly.

In-Wheel Motors and Modular Platforms

One of the most promising advancements in drivetrain design is the in-wheel motor. By integrating an electric motor directly into each wheel hub, manufacturers can eliminate the need for axles, differentials, and even traditional transmissions.

Benefits of in-wheel motors include:

- Complete independence of each wheel

- Highly precise torque vectoring

- Freer platform design for modular chassis (like skateboard platforms)

Automakers such as REE Automotive, Protean Electric, and Lordstown Motors are already exploring these technologies. While current drawbacks—like unsprung weight and cost—remain, advancements in materials and power electronics could make in-wheel drivetrains viable for mass production in the coming decade.

Drivetrain Customization Through Software Updates

Over-the-air (OTA) updates are transforming how we interact with drivetrain systems. What once required physical modifications can now be adjusted via a software patch. Tesla, Rivian, and other EV makers already use OTA updates to:

- Improve AWD traction algorithms

- Modify torque curves

- Introduce new drive modes (e.g., Off-Road Mode, Snow Mode)

As vehicles become increasingly connected and digital, we can expect subscription-based drivetrain features—such as temporary AWD enablement or performance boosts—based on user preferences.

Sustainability and Efficiency Goals

Future drivetrains will also be central to achieving broader sustainability objectives. This includes:

- Using lighter materials (aluminum, carbon composites) to reduce energy use

- Minimizing mechanical complexity to cut manufacturing emissions

- Maximizing energy regeneration through advanced braking systems

For EVs, this translates to drivetrains that are not just about moving the car, but also about preserving and recycling energy in every step of the driving process.

Integration with Autonomous Systems

In self-driving or semi-autonomous vehicles, the drivetrain must respond to a computer, not a human. This requires:

- Real-time communication with ADAS (Advanced Driver Assistance Systems)

- Coordination with navigation data to anticipate terrain

- Seamless adjustment of torque for safety and passenger comfort

The drivetrain will no longer be an isolated system—it will become part of a larger intelligent mobility architecture, responding instantly to external inputs such as road conditions, pedestrian proximity, or navigation reroutes.

The future of drivetrain technology is not just an evolution—it’s a reinvention. Driven by electric propulsion, digital control, and sustainable design, tomorrow’s drivetrains will be smarter, cleaner, and more capable than anything we’ve seen before. Whether embedded in an autonomous urban pod or a high-torque electric truck, the drivetrain will remain at the core of how vehicles move—but the rules of that movement are changing forever.

Conclusion

The drivetrain has always been a foundational element in vehicle engineering, quietly working behind the scenes to convert raw power into controlled motion. Whether it’s the front wheels pulling a compact city car, the rear wheels pushing a performance sedan, or all four wheels powering an electric SUV through snow-covered roads, the drivetrain dictates how a vehicle behaves under your command.

As we’ve explored, drivetrain systems come in various forms—each tailored to specific use cases. From the simplicity and efficiency of FWD, the performance edge of RWD, the all-weather capability of AWD, to the rugged utility of 4WD, each configuration reflects a balance of engineering trade-offs. And now, with the rapid shift toward electric vehicles, the concept of a drivetrain is undergoing a quiet revolution. Dual motors, in-wheel setups, and software-driven torque management are replacing shafts and gears, bringing unprecedented control, flexibility, and energy efficiency.

Yet no matter how advanced drivetrains become, the goal remains the same: to translate power into motion reliably, efficiently, and safely. Understanding the nuances of drivetrain systems—how they work, what affects their performance, and how they are evolving—is no longer just the domain of mechanics or engineers. It’s knowledge every driver can benefit from.

Whether you’re shopping for your next EV, exploring off-road adventures, or just curious about what powers your daily commute, the drivetrain is more than just a mechanical connection—it’s the core of how your car moves, and where automotive innovation is accelerating fastest.

FAQ About Drivetrain

What is a drivetrain in a car?

A drivetrain is the system of components that transfers power from a vehicle’s engine or electric motor to its wheels. It includes parts like the transmission, driveshaft, differential, and axles—everything involved in delivering motion, but excluding the power source itself.

How is a drivetrain different from a powertrain?

While a drivetrain handles the delivery of power to the wheels, a powertrain includes the entire system—from the engine or electric motor to the drivetrain components. In essence, the powertrain = power generation + power delivery.

Which drivetrain is best for snowy or slippery roads?

All-Wheel Drive (AWD) and Four-Wheel Drive (4WD) systems are ideal for snow and wet conditions. They provide better traction by sending power to all four wheels, improving grip and control on slick surfaces.

Do electric vehicles have different drivetrain systems?

Yes. EVs often use simpler drivetrains due to their electric motors, with many using a single-speed reduction gear. Dual-motor EVs also offer advanced AWD setups controlled by software rather than mechanical linkages.

How do I know which drivetrain type my car has?

You can find your vehicle’s drivetrain type in the owner’s manual, on the manufacturer’s website, or via the VIN (Vehicle Identification Number). It’s also visible through driving feel—such as torque steer in FWD or rear push in RWD.