As the push for cleaner transportation intensifies, most conversations around electric vehicles tend to orbit one dominant narrative: batteries. Lithium-ion technology has become the poster child of zero-emission driving, and for good reason—it’s proven, widespread, and backed by a fast-growing charging network. But there’s another electric technology quietly gaining ground, one that doesn’t plug in but still delivers clean, efficient motion: Hydrogen Fuel Cell Electric Vehicles (FCEVs).

Fuel Cell Electric Vehicles, or FCEVs, run on compressed hydrogen and emit nothing but water vapor. They offer fast refueling, long range, and smooth, silent performance—features that make them uniquely appealing in certain segments of the market. While less visible than battery EVs, FCEVs are not experimental. They’re real, operational, and already deployed across cities, highways, and industrial fleets around the world.

So why aren’t we seeing more of them? The answer lies in a mix of infrastructure gaps, production challenges, and policy momentum. But the technology itself is sound—and in many ways, brilliantly elegant.

In this article, we’ll explore what FCEVs are, how they work, where they excel (and where they struggle), and why hydrogen may still play a central role in the future of zero-emission transport—especially in places batteries can’t quite reach.

What Are Fuel Cell Electric Vehicles (FCEVs)?

While Electric Vehicles (EVs) are generally associated with plug-in charging and lithium-ion batteries, Fuel Cell Electric Vehicles (FCEVs) take a different route to electric mobility. Rather than storing electricity in large batteries, FCEVs generate electricity on demand through a chemical reaction between hydrogen and oxygen inside a fuel cell. The only byproduct? Water vapor.

At their core, FCEVs are electric vehicles, powered by an electric motor that drives the wheels. However, instead of drawing that power from a charged battery, the electricity is produced on the fly by a hydrogen fuel cell stack—a system that acts as a mini power plant under the hood.

FCEVs store compressed hydrogen gas in high-pressure tanks, typically at 700 bar (10,000 psi). When the vehicle is turned on, hydrogen flows from the tank into the fuel cell, where it meets oxygen from the outside air. Through a process called electrochemical conversion, the hydrogen atoms are split into protons and electrons. The electrons flow through an external circuit, creating electric current to power the motor, while the protons combine with oxygen to form water. This process is quiet, efficient, and emits no harmful gases.

What sets FCEVs apart from other EV types is their fast refueling time (often under five minutes) and long driving range, which can exceed 350–400 miles on a full tank—comparable to many gasoline-powered vehicles. These attributes make them particularly attractive for long-distance travel and commercial use, especially in segments where extended downtime for charging isn’t practical.

But FCEVs aren’t just about performance or convenience—they’re also about vision. In a world increasingly committed to carbon neutrality, hydrogen offers a pathway not only for clean vehicles but also for decarbonizing entire industries, from shipping to steel production. In this context, FCEVs represent more than a niche alternative—they’re a glimpse into a broader hydrogen economy that’s beginning to take shape.

Of course, they face real-world limitations. Hydrogen refueling infrastructure is still sparse, production methods vary in sustainability, and public awareness remains low compared to battery EVs. Still, as governments invest in hydrogen and automakers commit to diversified portfolios, FCEVs are steadily gaining traction as a complement—not a competitor—to battery electric vehicles.

How Do FCEVs Work?

At a glance, a fuel cell vehicle might resemble any other modern electric car—quiet, smooth, and efficient. But beneath the body panels, the mechanics of a Fuel Cell Electric Vehicle (FCEV) operate on a uniquely sophisticated principle: generating electricity as needed through an on-board chemical reaction between hydrogen and oxygen.

The heart of the system is the fuel cell stack. Inside this unit, hydrogen gas stored in high-pressure tanks is delivered to the anode, where it encounters a catalyst (typically platinum). The hydrogen molecules are split into protons and electrons. The protons pass through a special membrane (proton exchange membrane, or PEM), while the electrons are forced to travel through an external circuit, generating electric current to power the vehicle’s motor and onboard electronics.

Meanwhile, at the cathode side of the fuel cell, oxygen from the ambient air combines with the protons and electrons to form H₂O—plain water—which is then expelled from the tailpipe as vapor. This electrochemical process is clean, continuous, and efficient, providing a steady stream of electricity without combustion or harmful emissions.

Key Steps in the FCEV Power Process

- Hydrogen is stored in pressurized tanks (typically 5–7 kg at 700 bar).

- Hydrogen enters the fuel cell stack, where it’s split into protons and electrons.

- Electricity is generated as electrons move through the circuit.

- Electric motor is powered using the electricity.

- Water vapor is released as the only emission.

To ensure consistent power delivery, most FCEVs include a small battery or supercapacitor. This auxiliary system helps manage:

- Regenerative braking (storing energy when decelerating),

- Instant torque response, and

- Power buffering, smoothing out acceleration demands.

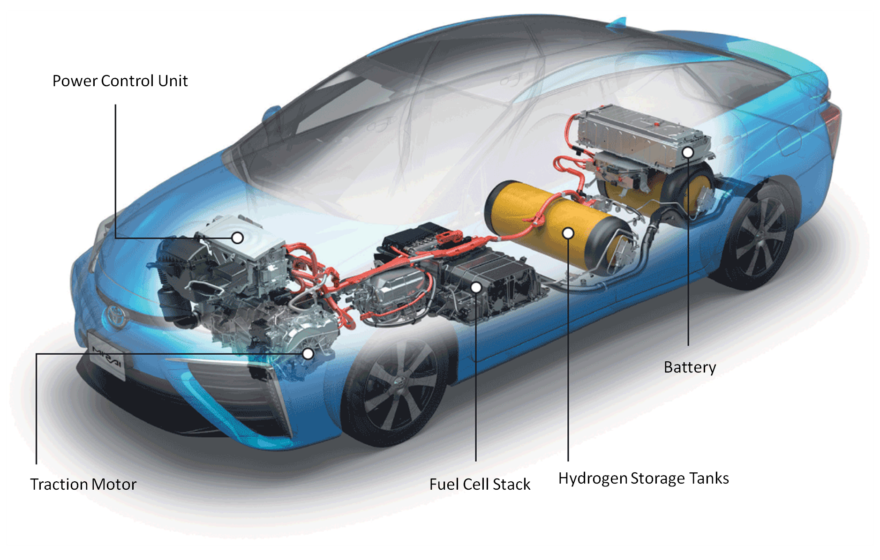

Major Components of an FCEV

- Fuel Cell Stack – Generates electricity from hydrogen and oxygen

- Hydrogen Storage Tanks – Hold hydrogen gas under high pressure

- Battery Buffer System – Stores regenerated energy and boosts performance

- Electric Motor – Converts electric energy into mechanical power

- Power Control Unit (PCU) – Regulates energy flow to motor and auxiliary systems

Unlike battery EVs, which must be charged in advance, FCEVs generate electricity on the fly. The driving experience is still fully electric—instant torque, smooth acceleration, quiet operation—but the “fuel” is hydrogen, not stored electricity. This on-demand energy generation is what enables fast refueling and long driving range, even with a smaller onboard energy storage footprint.

As infrastructure improves and hydrogen becomes more widely available (especially green hydrogen), the simplicity and elegance of this system may prove to be a major advantage for both personal and commercial transportation sectors.

Key Components of an FCEV

Fuel Cell Electric Vehicles (FCEVs) rely on a specialized set of components that enable them to produce electricity onboard and deliver smooth, zero-emission performance. While they share some similarities with battery electric vehicles (BEVs), the core systems are engineered around hydrogen fuel cell operation rather than stored electrical energy.

Here’s a closer look at the main components that make an FCEV function:

Fuel Cell Stack

This is the heart of the vehicle. A fuel cell stack consists of multiple individual fuel cells layered together. Each cell combines hydrogen and oxygen to generate electricity through an electrochemical process. The output is direct current (DC) electricity, which powers the vehicle’s electric motor or charges a small onboard battery. The only byproduct of this process is water vapor.

The efficiency and durability of the fuel cell stack are central to an FCEV’s performance. It must operate reliably across a wide range of temperatures and driving conditions, all while maintaining consistent output and longevity.

Hydrogen Storage Tanks

FCEVs store compressed hydrogen gas in high-strength, carbon-fiber-reinforced tanks. These tanks are designed to safely hold hydrogen at very high pressures—typically 700 bar (10,000 psi). Most passenger FCEVs carry between 5 to 7 kilograms of hydrogen, providing a driving range of 300 to 400 miles depending on efficiency.

Safety is a top priority in hydrogen tank design. The tanks undergo rigorous crash testing and are built to withstand extreme conditions, making hydrogen storage in modern FCEVs both reliable and secure.

Electric Motor

Like all electric vehicles, FCEVs use an electric motor to drive the wheels. The motor converts electrical energy—generated by the fuel cell stack—into mechanical energy. These motors provide instant torque, quiet operation, and smooth acceleration, similar to battery electric vehicles.

The EV Powertrain is typically single-speed and requires far fewer moving parts than traditional internal combustion engines, which contributes to lower maintenance requirements.

Battery Buffer System

While FCEVs don’t rely on large battery packs like BEVs, they do include a smaller battery—often lithium-ion or nickel-metal hydride—to act as a buffer. This battery stores excess energy recovered from regenerative braking and assists the fuel cell during moments of high power demand, such as quick acceleration or hill climbing.

The buffer system enhances energy efficiency and responsiveness without significantly increasing vehicle weight.

Power Control Unit (PCU)

This component serves as the vehicle’s energy manager. It regulates the flow of electricity from the fuel cell stack and the battery to the electric motor, ensuring optimal power delivery. The PCU also oversees charging of the buffer battery and maintains system efficiency across varying loads and driving conditions.

In essence, the PCU makes real-time decisions to balance supply and demand, contributing to smooth and efficient driving performance.

Together, these components form a tightly integrated system that delivers the benefits of electric mobility—quiet operation, instant torque, zero emissions—without the limitations of long charging times or EV range anxiety. While the technology is complex, its design is centered around simplicity for the driver: refuel, drive, repeat.

Advantages of Fuel Cell Vehicles

Fuel Cell Electric Vehicles (FCEVs) offer a unique blend of performance, convenience, and environmental benefits that distinguish them from both traditional combustion engines and battery electric vehicles. While they may not yet be as widespread, FCEVs possess key strengths that make them an attractive solution in specific transportation scenarios—particularly where fast refueling, long range, and zero emissions are essential.

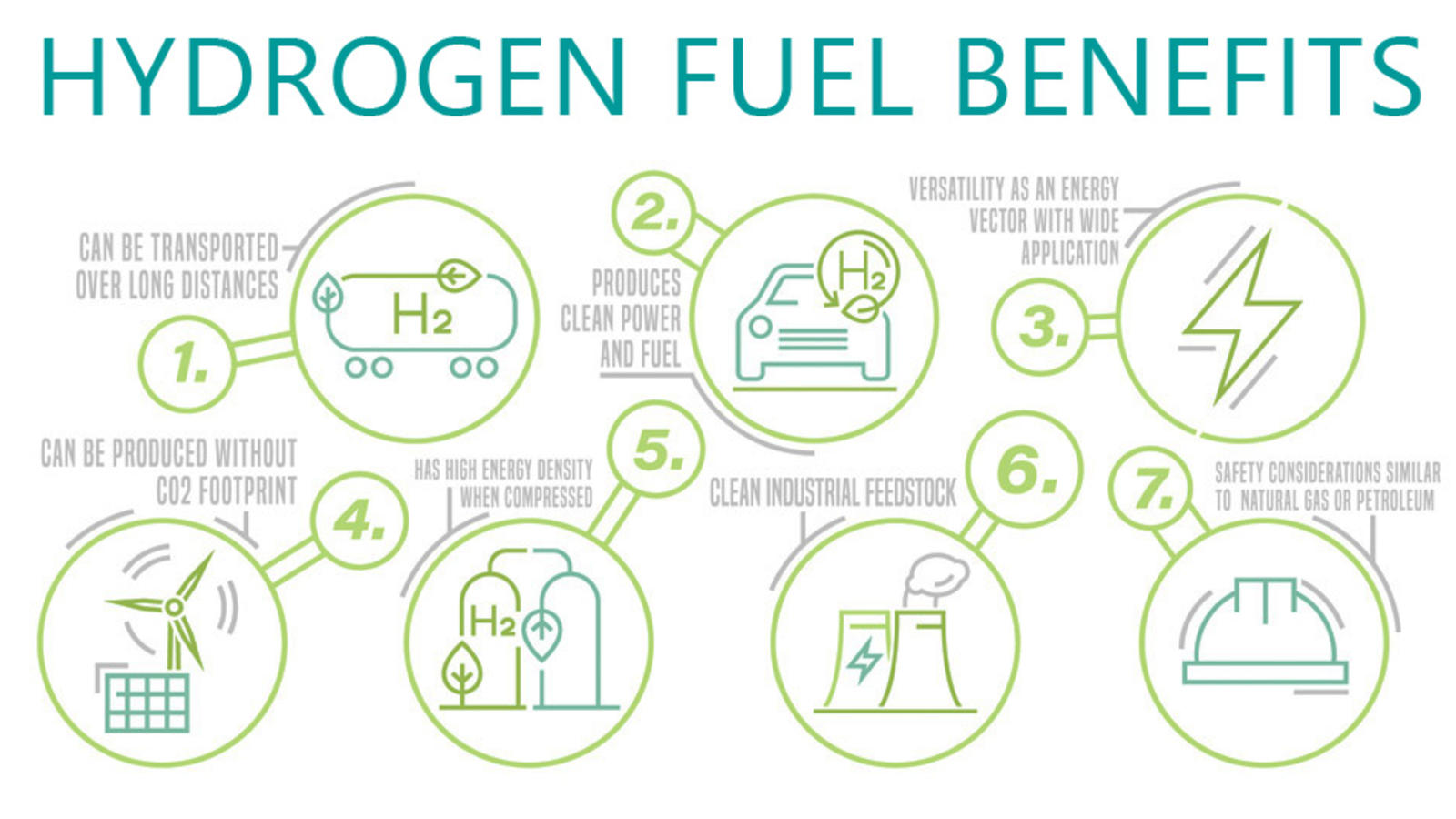

Zero Tailpipe Emissions

Perhaps the most critical advantage of FCEVs is that they produce no tailpipe emissions other than water vapor. Since the hydrogen fuel cell produces electricity through an electrochemical reaction—rather than combustion—there are no carbon emissions, particulates, or nitrogen oxides released into the air. This positions FCEVs as a viable option for cities and regions targeting aggressive decarbonization and air quality goals.

Fast Refueling

One of the limitations of battery electric vehicles is the time required to recharge, which—even with fast-charging infrastructure—can range from 30 minutes to several hours. In contrast, FCEVs can be refueled in roughly 3 to 5 minutes, similar to filling a gasoline tank. This rapid turnaround time makes them highly practical for fleets, taxis, delivery vehicles, and drivers who need minimal downtime.

Long Driving Range

FCEVs typically offer driving ranges of 300 to 400 miles per tank, putting them on par with, or even exceeding, many internal combustion and battery-powered vehicles. This extended range is particularly beneficial for drivers in rural areas, long-distance commuters, or commercial operators who cover large distances daily.

Consistent Performance Regardless of Weather

Unlike battery systems that may degrade or lose efficiency in cold temperatures, fuel cells tend to maintain more consistent output across various climates. This makes FCEVs more reliable in environments with extreme heat or cold, where battery EV performance may suffer.

Lightweight Energy Storage

Hydrogen contains significantly more energy per unit of weight than lithium-ion batteries. As a result, FCEVs can achieve long range without requiring massive battery packs. This leads to lighter vehicles, especially for applications like buses or trucks, where weight efficiency plays a major role in design and operational cost.

Quiet and Smooth Operation

Just like battery EVs, FCEVs are quiet, with minimal vibration or noise. The electric motor provides smooth and linear acceleration, contributing to a refined and comfortable driving experience. This not only benefits the driver but also reduces noise pollution in urban environments.

Potential for Renewable Integration

When hydrogen is produced through electrolysis powered by renewable energy (also known as green hydrogen), the full lifecycle of an FCEV—from fuel production to vehicle operation—can become entirely carbon-neutral. This opens a pathway toward 100% clean mobility, especially when hydrogen production is integrated with solar, wind, or hydropower infrastructure.

Scalability for Heavy Transport

FCEV technology scales well for larger vehicles. While battery packs become heavier and more cost-prohibitive at scale, fuel cells offer a better weight-to-energy ratio. This makes them especially promising for heavy-duty vehicles such as buses, freight trucks, trains, and even maritime transport.

While fuel cell vehicles are not a perfect solution for every use case, their unique strengths address specific pain points in the electrification landscape—especially where fast refueling and long-distance operation are crucial.

Challenges and Limitations of FCEVs

While Fuel Cell Electric Vehicles (FCEVs) offer compelling advantages—zero emissions, fast refueling, long range—they also face a number of critical challenges that have slowed widespread adoption. Understanding these limitations is essential to assessing the true potential of hydrogen-powered mobility in both the short and long term.

Limited Hydrogen Infrastructure

The most pressing obstacle for FCEVs is the lack of refueling stations. Unlike electric vehicle charging networks, which have grown rapidly in many countries, hydrogen fueling infrastructure remains highly localized. For instance, in the United States, public hydrogen stations are almost exclusively found in California. In most other regions, access is either minimal or non-existent.

This limited availability makes FCEVs impractical for mainstream consumers, restricting their use to areas where refueling is possible. For fleet operations or pilot programs, infrastructure can be installed on-site, but that requires significant investment.

High Vehicle and Technology Costs

Fuel cell technology remains more expensive to produce than both internal combustion engines and battery-electric powertrains. The fuel cell stack, hydrogen tanks, and supporting components require specialized materials and precision engineering, which adds to the cost of the vehicle.

In addition, production volumes are still low, meaning economies of scale have yet to bring prices down significantly. While government incentives may offset some of the cost, FCEVs generally remain more expensive upfront than battery electric or hybrid vehicles.

Hydrogen Production Is Not Always Clean

Although FCEVs themselves produce no tailpipe emissions, hydrogen production can carry a heavy carbon footprint. The vast majority of hydrogen today is produced through steam methane reforming, a process that emits large quantities of carbon dioxide. This type of hydrogen is known as gray hydrogen.

Cleaner alternatives, such as blue hydrogen (with carbon capture) or green hydrogen (produced via electrolysis using renewable energy), are more environmentally friendly—but also more expensive and less available at scale. Until the hydrogen supply chain becomes cleaner, the full environmental benefit of FCEVs will remain limited.

Energy Efficiency

FCEVs are less energy-efficient than battery electric vehicles when considering the entire well-to-wheel cycle. Converting electricity to hydrogen (via electrolysis), compressing and transporting it, then converting it back to electricity in a fuel cell introduces multiple stages of energy loss.

In contrast, battery EVs can store and use electricity more directly, with fewer conversion steps. As a result, battery EVs remain the more efficient option in most scenarios, especially where charging is readily accessible.

Public Perception and Market Readiness

Despite their benefits, FCEVs are still relatively unknown to the average consumer. Most people are more familiar with BEVs and hybrids, and hydrogen is often perceived as risky or futuristic, partly due to associations with flammability and complexity.

While modern FCEVs meet strict safety standards and are no more dangerous than gasoline vehicles, overcoming these misconceptions will take public education and real-world exposure, both of which require time and coordinated effort.

Maintenance and Service Complexity

FCEVs have fewer moving parts than traditional combustion vehicles, but their systems—particularly the fuel cell stack and hydrogen storage components—require specialized knowledge and equipment for diagnostics and servicing. Many repair shops and dealerships are not yet equipped or trained to handle fuel cell systems, limiting service accessibility for owners.

Despite these challenges, fuel cell vehicles are not without a future. Many of these limitations—especially infrastructure and production costs—can be addressed through sustained investment, innovation, and policy support. But for now, these factors explain why FCEVs remain a niche technology, even in markets with growing environmental commitments.

FCEV vs Other Electric Vehicle Types

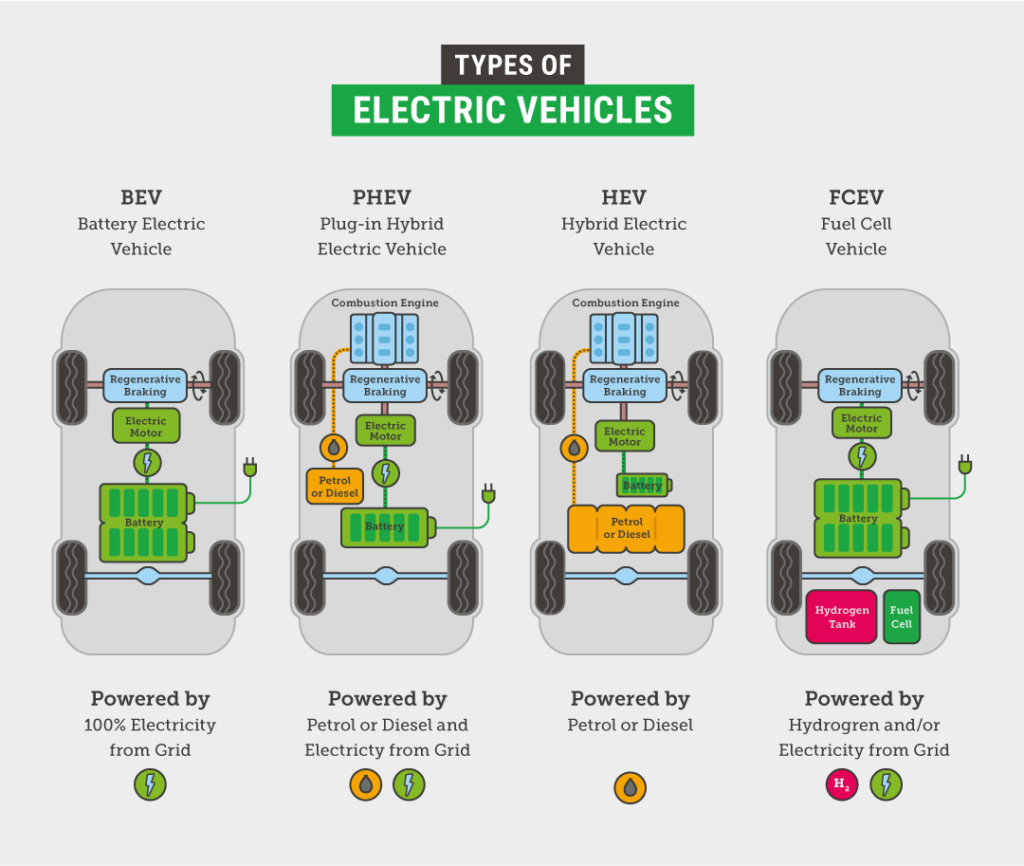

Fuel Cell Electric Vehicles (FCEVs) occupy a unique position in the electrified mobility landscape. While they share many characteristics with other electric vehicles, their underlying technology, fueling method, and infrastructure requirements set them apart.

To fully understand their role, it’s essential to compare FCEVs to the three other major categories of electrified vehicles: Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Hybrid Electric Vehicles (HEVs).

FCEV vs BEV (Battery Electric Vehicle)

Battery Electric Vehicles (BEVs) run entirely on electricity stored in large batteries and require external charging. They are currently the most common form of electric vehicle on the road, with models like the Tesla Model 3, Nissan Leaf, and Hyundai Ioniq 5 leading global adoption.

Key Differences:

- Energy Storage: FCEVs generate electricity on demand via hydrogen; BEVs store electricity in a battery.

- Refueling vs Charging: FCEVs refuel in 3–5 minutes; BEVs require 30 minutes to several hours depending on the charger.

- Infrastructure: BEVs benefit from growing charging networks; FCEVs suffer from limited hydrogen stations.

- Efficiency: BEVs are more energy-efficient on a per-mile basis.

- Environmental Impact: BEVs depend on electricity source; FCEVs’ environmental benefit depends on how hydrogen is produced.

BEVs are ideal for urban driving and areas with charging access. FCEVs shine where range and fast refueling are priorities—especially in fleet or long-distance use cases.

FCEV vs PHEV (Plug-in Hybrid Electric Vehicle)

PHEVs offer a blend of gasoline and electric power. They have a small battery that can be charged and used for short electric-only trips, but switch to gasoline when the battery is depleted.

Key Differences:

- Power Source: PHEVs use both gasoline and battery power; FCEVs use only hydrogen to generate electricity.

- Emissions: PHEVs produce emissions during gasoline use; FCEVs have zero tailpipe emissions.

- Range Flexibility: PHEVs can go long distances using gasoline; FCEVs rely on hydrogen availability.

- Refueling: PHEVs can use any gas station and plug in at home; FCEVs require dedicated hydrogen stations.

PHEVs are a transitional technology for drivers not ready to go fully electric. FCEVs provide a fully electric driving experience with zero emissions but require new infrastructure.

FCEV vs HEV (Hybrid Electric Vehicle)

HEVs are conventional hybrids that do not plug in. They use a combination of a gasoline engine and an electric motor that’s recharged through regenerative braking and engine operation.

Key Differences:

- Electrification: HEVs assist with electric power but rely mainly on gasoline; FCEVs are entirely electric.

- Emissions: HEVs produce emissions; FCEVs do not.

- Refueling: Both use quick refueling, but HEVs use gas stations, and FCEVs require hydrogen.

- Complexity: HEVs have mature technology and global availability; FCEVs are newer and less widespread.

HEVs are more affordable and readily available but do not eliminate emissions. FCEVs are more sustainable in the long term, assuming infrastructure is in place.

| Feature | FCEV | BEV | PHEV | HEV |

|---|---|---|---|---|

| Primary Power Source | Hydrogen fuel cell (generates electricity) | Battery (charged from power grid) | Battery + Gasoline engine | Gasoline engine + electric assist |

| Tailpipe Emissions | None (only water vapor) | None | Low (when gasoline is used) | Yes (gasoline-dependent) |

| Fueling/Charging Time | 3–5 minutes (hydrogen) | 30 min to several hours (charging) | Gasoline: 5 min; Charging: 1–4 hours | 5 minutes (gasoline) |

| Driving Range | 300–400 miles | 150–400+ miles (varies by battery size) | 20–50 miles electric + 300+ miles gas | 500–600 miles |

| Refueling Infrastructure | Very limited (mostly in select regions) | Expanding charging network globally | Universal (gas) + growing charging access | Universal (gas stations) |

| Upfront Vehicle Cost | High | Moderate to high | Moderate | Lower |

| Maintenance Needs | Low (but requires specialized service) | Low | Moderate | Moderate |

| Best Use Case | Long-distance, fleet, low-emission transport | Urban/suburban driving with home charging | Short trips + gasoline backup flexibility | General use with better fuel economy |

Each Types of Electric Vehicles offers distinct advantages depending on the driver’s location, habits, and values. While BEVs are leading the electric revolution, FCEVs are carving a niche in sectors where quick refueling, long range, and heavy-duty performance are non-negotiable.

10 Real-World Examples of FCEVs

Despite limited visibility in the mainstream market, Fuel Cell Electric Vehicles (FCEVs) are already here—and they’re not just theoretical. Across Asia, Europe, and parts of North America, hydrogen-powered vehicles are being deployed in real-world conditions, from city roads to industrial corridors.

Some are available to the public, while others are purpose-built for logistics, transit, or demonstration fleets. Together, they provide a compelling look at how hydrogen fuel cell technology is evolving beyond prototypes into practical, scalable transportation solutions.

Below are ten notable examples of FCEVs, spanning passenger vehicles, commercial applications, heavy-duty freight, and experimental designs.

1. Toyota Mirai (Passenger Car)

The Toyota Mirai was one of the first commercially available hydrogen-powered vehicles and remains a benchmark in the segment. With a range of up to 402 miles and a refueling time under five minutes, the Mirai offers a compelling alternative to battery EVs for those who have access to hydrogen infrastructure.

It’s currently sold primarily in California, Japan, and select markets in Europe, where hydrogen stations are more developed. Toyota continues to refine the Mirai platform as part of its long-term hydrogen mobility strategy.

2. Hyundai Nexo (Passenger SUV)

Hyundai’s Nexo is a sleek, midsize hydrogen-powered SUV that combines advanced tech with strong environmental credentials. It offers up to 380 miles of range, a spacious cabin, and a range of smart safety features.

The Nexo is often deployed in pilot projects or government-backed green transport initiatives, particularly in South Korea and parts of Europe. It demonstrates how FCEVs can integrate seamlessly into family-oriented, everyday driving contexts.

3. Honda Clarity Fuel Cell (Passenger Sedan)

:strip_icc():format(jpeg)/kly-media-production/medias/4283979/original/065815400_1673011122-honda_fcx_2008_photos_3_1600x1200.jpg)

The Clarity Fuel Cell was Honda’s answer to early hydrogen adoption, available through limited leasing programs in California. It offered a smooth, quiet ride and around 360 miles of range.

While production was discontinued in 2021, the Clarity played a key role in hydrogen tech validation and infrastructure development in the United States. It helped shape early consumer feedback on usability, efficiency, and performance.

4. BMW iX5 Hydrogen (Concept SUV)

The iX5 Hydrogen is a hydrogen-powered version of BMW’s popular X5 SUV, unveiled in limited pilot programs starting in 2023. It utilizes Toyota’s fuel cell stack technology paired with BMW’s electric architecture.

With a range around 300 miles and high-speed performance, the iX5 demonstrates the premium potential of FCEVs in the luxury segment. BMW sees hydrogen as a complement to its growing battery EV portfolio, particularly for long-distance or high-load applications.

5. Mercedes-Benz GLC F-CELL (Plug-in FCEV Hybrid)

,xPosition=0,yPosition=0.5)

This vehicle combined plug-in battery functionality with hydrogen capability, offering dual-mode electric driving. While it was never mass-produced, the GLC F-CELL showcased an innovative approach to transitional vehicle technology.

It could be plugged in like a traditional EV or refueled with hydrogen, providing flexibility in infrastructure-limited regions.

6. Nikola Tre FCEV (Heavy-Duty Truck)

Developed by Nikola Motors, the Tre is a hydrogen-powered Class 8 truck aimed at long-haul freight operations. With an estimated range of 500 miles and refueling times under 20 minutes, it’s being positioned as a zero-emission alternative to diesel in logistics and freight transportation.

The Tre is currently undergoing pilot testing in North America and Europe, backed by growing support for clean freight corridors.

7. Hyundai XCIENT Fuel Cell Truck (Commercial Freight Vehicle)

Hyundai’s XCIENT is a heavy-duty truck that has already seen commercial deployment in Switzerland and South Korea. It features multiple hydrogen tanks and delivers up to 400 miles of range.

Used primarily for regional logistics and cargo transport, the XCIENT represents one of the most mature FCEV freight platforms in the world.

8. Toyota Sora (Public Transit Bus)

The Toyota Sora is a fuel cell electric bus used in Tokyo’s public transportation system. With silent operation, zero emissions, and energy-efficient systems, it’s been praised for both rider comfort and environmental impact.

It served as a showcase vehicle during events like the Tokyo Olympics, illustrating Japan’s vision for a hydrogen-powered society.

9. Hyzon Motors Trucks & Buses (Commercial Fleet Vehicles)

Hyzon Motors is a hydrogen mobility startup focusing exclusively on fuel cell trucks and buses. Its products are designed for municipal fleets, logistics companies, and specialized industrial uses.

Hyzon has operational vehicles in Australia, Europe, and North America, and is working to scale up manufacturing capacity for broader adoption.

10. Riversimple Rasa (Prototype City Commuter)

This British-made, ultra-lightweight prototype is a two-seater city car with a range of about 300 miles and a design philosophy centered around minimal environmental impact. The Rasa weighs just 580 kg and uses a small hydrogen fuel cell paired with regenerative braking.

While not yet commercialized, it’s an example of how FCEV technology can be adapted for urban micro-mobility and efficiency-focused transport.

Summary Table: FCEVs by Category

| Category | Vehicle Name | Manufacturer | Range (mi) | Refueling Time | Status / Use Case |

|---|---|---|---|---|---|

| Passenger Car | Toyota Mirai | Toyota | ~402 | 3–5 min | Mass-produced, public sale |

| Passenger SUV | Hyundai Nexo | Hyundai | ~380 | 5 min | Retail + government fleets |

| Passenger Sedan | Honda Clarity Fuel Cell | Honda | ~360 | 3–5 min | Discontinued, lease only |

| Luxury SUV (Concept) | BMW iX5 Hydrogen | BMW | ~300 | 4–5 min | Pilot programs (EU, Asia) |

| Hybrid SUV | Mercedes-Benz GLC F-CELL | Mercedes-Benz | ~270 | 3–4 min | Test fleets in Germany |

| Heavy Truck | Nikola Tre FCEV | Nikola Motors | ~500 | ~15–20 min | Pilot stage (US, EU) |

| Heavy Truck | Hyundai XCIENT | Hyundai | ~400 | ~10–15 min | Commercial ops (CH, KR) |

| Transit Bus | Toyota Sora | Toyota | ~120+ | Depot refill | Public buses (Tokyo) |

| Fleet (Trucks/Buses) | Hyzon Motors Fleet | Hyzon Motors | ~400+ | ~10 min | Active (US, EU, AUS) |

| City Commuter (Prototype) | Riversimple Rasa | Riversimple | ~300 | ~5 min | Prototype, testing phase |

Hydrogen Infrastructure: Where We Are Today

The success of Fuel Cell Electric Vehicles (FCEVs) depends not just on the vehicles themselves but on the hydrogen infrastructure that supports them. Without an accessible, reliable, and scalable network of hydrogen production, storage, and refueling stations, even the most advanced FCEVs cannot thrive beyond small pilot programs or isolated regions.

So where do we stand today in terms of infrastructure—and what needs to happen next?

Global Overview

As of mid-2025, hydrogen refueling infrastructure is still limited and region-specific, though progress is accelerating in key markets:

- Japan is among the global leaders, with over 150 hydrogen stations in operation and government-supported plans to expand that number significantly. The country’s “Hydrogen Society” vision positions fuel cell vehicles as a cornerstone of clean mobility.

- South Korea is aggressively building hydrogen infrastructure under its national hydrogen roadmap, aiming for over 300 stations by 2030 and making hydrogen central to both public and commercial transport strategies.

- Germany and other EU nations (like France and the Netherlands) are part of the Hydrogen Europe initiative, developing transnational hydrogen corridors and truck-ready refueling hubs to support both FCEVs and heavy-duty logistics.

- California remains the only U.S. state with meaningful infrastructure, with approximately 55 publicly accessible stations, mostly in urban or coastal zones. While several other states have announced plans, execution has lagged behind policy.

- China is expanding rapidly, particularly in industrial hydrogen zones where fuel cell buses and delivery vehicles are being trialed at scale.

Despite this progress, most of the world lacks hydrogen refueling access, which severely limits the mass-market potential of FCEVs.

Refueling Station Design & Technology

Hydrogen stations operate differently from electric chargers. They are complex, high-pressure systems that require specialized equipment to store and dispense hydrogen gas safely—typically at 700 bar for passenger vehicles and 350 bar for commercial trucks and buses.

Modern stations include:

- Cryogenic or compressed storage tanks

- High-pressure dispensers

- On-site or trucked-in hydrogen supply

- Advanced leak detection and safety systems

Some stations use on-site electrolysis to produce hydrogen using electricity (preferably from renewables), while others rely on bulk delivery from centralized facilities using pipelines or tanker trucks.

The high cost of building a single hydrogen station—often exceeding $1 million USD—has slowed deployment compared to electric charging, but costs are gradually falling as technology matures and economies of scale improve.

Challenges in Infrastructure Rollout

Several barriers are currently limiting faster hydrogen station deployment:

- High capital expenditure

Hydrogen stations are significantly more expensive to build and maintain than EV charging points or gas stations. - Regulatory complexity

Strict zoning, environmental, and safety requirements can delay construction or approval for months or even years. - Low demand loop

Automakers hesitate to release FCEVs without stations; infrastructure providers hesitate to build stations without vehicles—creating a chicken-and-egg scenario. - Geographic fragmentation

Most existing infrastructure is clustered in urban hubs, with very few long-distance corridors fully supported. This creates “islands” of usability for FCEV owners.

The Road Ahead

Governments and private stakeholders are actively working to address these issues:

- Public-private partnerships are funding station development across North America, Europe, and Asia.

- New policies are incentivizing green hydrogen production, especially through renewable-powered electrolysis.

- Infrastructure-as-a-service models are emerging, allowing fleet operators to build or co-invest in hydrogen hubs.

- Automotive manufacturers like Toyota, Hyundai, and Nikola are co-developing stations with fuel suppliers and energy companies.

The future of hydrogen mobility hinges not just on the cars and trucks themselves but on the ecosystem—and right now, that ecosystem is growing, but not yet mature.

Is FCEV the Future of Mobility?

Fuel Cell Electric Vehicles (FCEVs) sit at a crossroads between aspiration and reality. Technologically, they’re impressive: silent, clean, fast to refuel, and capable of long-range driving. For fleets, heavy-duty transport, and regions focused on energy diversity, FCEVs offer clear advantages over both combustion engines and battery electric vehicles. In short, they solve some of the biggest pain points in the EV transition—range, downtime, and scalability—especially for logistics and commercial use.

But the path forward isn’t simple.

Today, FCEVs face a combination of economic, infrastructural, and perceptual barriers. Hydrogen refueling networks remain sparse. Vehicle prices are high. Public understanding is low. And the hydrogen supply chain—while improving—is still heavily reliant on carbon-intensive production methods. These constraints have kept FCEVs in the background while battery EVs surge ahead in adoption.

However, that doesn’t mean hydrogen’s role is marginal. On the contrary, governments and industry leaders increasingly view hydrogen as a critical pillar of decarbonization—not just for mobility, but for heating, industrial energy, and energy storage. In this broader vision, FCEVs are a key application—especially where batteries fall short.

In the coming decade, we are likely to see FCEVs flourish in specific domains:

- Long-haul freight and logistics, where fast refueling and long range are essential.

- Public transportation, such as buses in cities aiming for zero-emissions infrastructure.

- Fleet vehicles with predictable routes, enabling investment in localized hydrogen hubs.

- Regions with excess renewable energy, where green hydrogen can be produced and used efficiently.

Meanwhile, battery electric vehicles will continue to dominate the consumer passenger space—at least until hydrogen infrastructure matures to a point where FCEVs become convenient and affordable for the average driver.

Ultimately, the future of mobility is not a zero-sum game between batteries and hydrogen. It’s a multi-path transition, where the right solution depends on context. FCEVs are not here to replace BEVs or hybrids—they’re here to complement them.

As the world races toward a carbon-neutral future, hydrogen-powered transportation may not be the fastest horse today—but it could prove to be one of the most strategic in the long run.

Frequently Asked Questions About Fuel Cell Electric Vehicles (FCEVs)

What is a Fuel Cell Electric Vehicle (FCEV)?

An FCEV is an electric vehicle that generates its own electricity using a chemical reaction between hydrogen and oxygen in a fuel cell. Unlike battery electric vehicles, which store electricity, FCEVs produce power on-demand and emit only water vapor.

How is an FCEV different from a BEV?

While both are electric vehicles, BEVs rely entirely on stored battery power and require charging, often for several hours. FCEVs use hydrogen to produce electricity internally and can be refueled in just 3–5 minutes. However, BEVs have better infrastructure support, while FCEVs offer faster refueling and longer range in some cases.

Are Fuel Cell Vehicles safe?

Yes, modern FCEVs are designed with rigorous safety standards. Hydrogen tanks are built with high-strength carbon-fiber composites, undergo extreme crash testing, and include multiple layers of protection. Hydrogen is also lighter than air, which allows it to dissipate quickly in case of a leak.

Where can I refuel a hydrogen car?

Hydrogen refueling stations are still limited and mostly available in select regions such as California (USA), parts of Japan, South Korea, and Germany. Infrastructure is expanding, but access remains one of the biggest barriers to mass FCEV adoption.

How far can a hydrogen car drive on a full tank?

Most passenger FCEVs offer between 300 to 400 miles of driving range on a full hydrogen tank. This is comparable to many gasoline-powered cars and typically greater than many battery EVs, especially in cold weather conditions.